-

-

Core manufacturer数字Our AdvantageApplicationOur honor certificate

-

Case classification

Xinjiang Dongfang Xiwang Nonferrous Metals Co., LTD. (hereinafter referred to as "Xinjiang Xilu") is a wholly-owned subsidiary of Dongfang Xiwang Group, a large private enterprise in China, and an important pillar industry of Dongfang Xiwang Xinjiang Heavy Industry. Xinjiang Xilu was established on December 30, 2010, in the Wucaiwan Industrial Park, Jimusar County, Changji Prefecture, Xinjiang. It will build a large-scale modern aluminum and electricity integrated factory. After the project is completed, it will become the largest aluminum and electricity integrated enterprise in China and even the world, bringing a great impetus to the regional economic development and promoting and advancing the national "Belt and Road" development strategy.

1.Project overview

The self-owned power plant of Xinjiang Dongfang Hope Nonferrous Metals Co., LTD. (hereinafter referred to as "New Aluminum Power Plant") is a power plant established by Xinjiang Heavy Industry of Dongfang Hope to build it into the world's largest aluminum and electricity integrated enterprise. The 5X350MW critical pressure boiler unit built in the first phase has been fully put into production and operation since the beginning of 2014.

2. Boiler system

Units 1 and 2 of Xinjiang Dongfang Hope Nonferrous Metals Co., LTD. 's self-owned power plant are 2×350MW coal-fired generating units. The boilers are subcritical parameter, four-corner circular combustion, natural circulation drum boilers produced by Dongfang Boiler Co., LTD. The operating efficiency of the fan under various working conditions is below 60%, which is relatively low and leaves a huge space for energy conservation.

3. One-time system solution

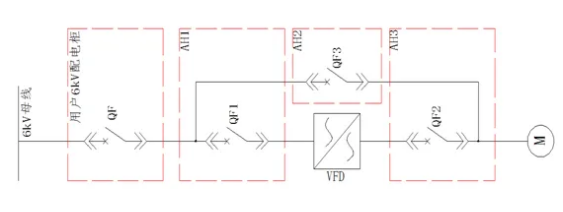

To meet the requirement that the primary fan can start and operate simultaneously at industrial frequency, the system adopts the FGI FD5000S medium voltage drive to improve reliability.

QF is a 6KV section circuit breaker for users, equipped with a comprehensive protection device.

QF1 is the input circuit breaker of the frequency converter, QF2 is the output circuit breaker of the frequency converter, and QF3 is the bypass circuit breaker of the industrial frequency.

There is an electrical interlock between QF2 and QF3. Once one circuit breaker is closed, the other cannot be closed.

4. Operation results

In November 2017, Xinjiang Xilu, in order to implement the group's value concept of making every effort to create the relative advantages of the enterprise, promoted the energy-saving technological transformation project of the primary fans of Units 1 and 2 of Xinjiang Xilu Power Plant. The procurement of high-voltage frequency converters for this renovation was carried out in the form of public bidding. Based on the principles of fairness, impartiality and transparency, the FGI FD5000 series high-voltage frequency converter products were finally selected, totaling 4 sets. All the equipment was fully installed and positioned in January 2018. Four sets of equipment were successfully debugged at one time and put into full production operation in March 2018. They smoothly passed the 168-hour assessment within the factory, and all indicators met the design requirements. From the perspective of actual usage, the adoption of FGI brand high-voltage frequency converters for primary fans has the following advantages:

(1) High control accuracy and obvious energy-saving effect. When the boiler load is 70%, the electricity-saving rate is 43%; when the boiler load is 80%, the electricity-saving rate is 33%.

(2) The inverter system has a high efficiency, with an inverter efficiency of over 97%.

(3) Improve the system power factor to above 0.96.

(4) It starts smoothly with a small starting current, which is convenient for achieving automatic control.

(5) It can achieve true soft start, causing no impact on the motor and the power grid, reducing the failure rate of the fan and the motor, and lowering maintenance costs.

(6) Easy to maintain; The transformation and commissioning period is short. When a fault occurs, it can be switched to power frequency operation. The fan can be switched to power frequency operation without stopping the machine, improving reliability.

Practice has proved that the selection of FGI FD5000 medium voltage drive for the frequency conversion transformation of Furnace No. 1 and Furnace No. 2 this time is successful, and the energy-saving effect has reached the expected result. The medium voltage drive was successfully debugged in one go from installation, commissioning to the final operation of the equipment. The product performance is advanced, the production and manufacturing process is excellent, and the product quality is reliable. All indicators meet the requirements of the production system.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project