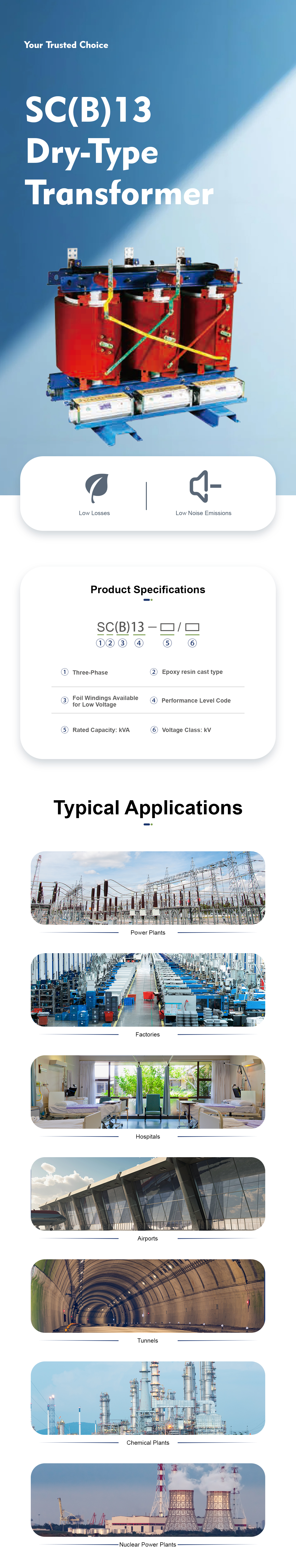

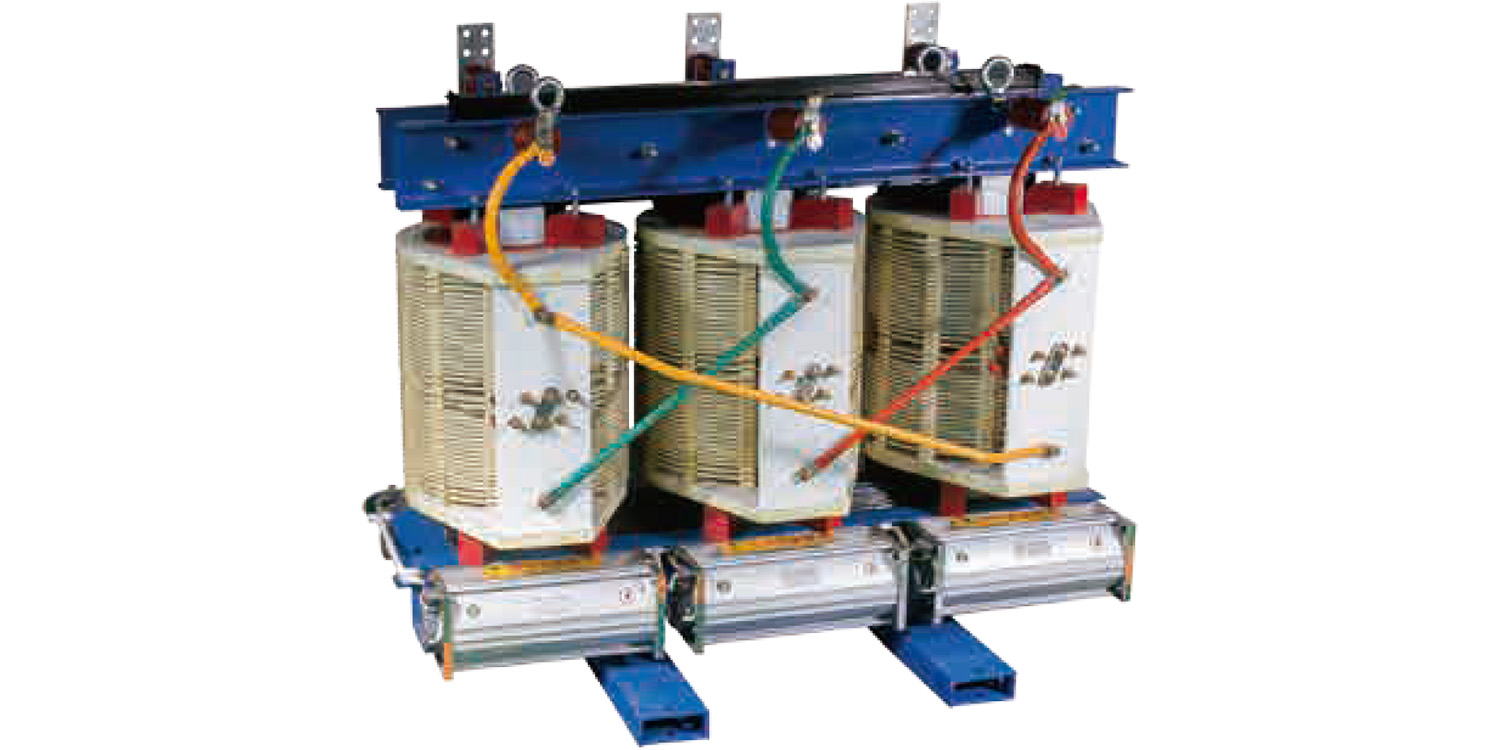

SC(B)13 type dry-type transformer

Due to the advantages of dry-type transformers such as strong short-circuit resistance, low maintenance workload, high operating efficiency, small size and low noise, they are often used in fire prevention,Places with high performance requirements such as explosion-proof.

Safe, fireproof, pollution-free, and can operate directly under high-load power consumption. Adopting advanced domestic technology, it features high mechanical strength, strong short-circuit resistance, low partial discharge, good thermal stability, high reliability and long service life.Low loss, low noise, obvious energy-saving effect, and maintenance-free.