-

-

Core manufacturer数字Our AdvantageApplicationOur honor certificate

-

Case classification

1.Introduction

Zhejiang Leo Co., Ltd. is the first listed company in China's micro and small water pump industry and the largest manufacturer and exporter of micro and small water pumps and branch shredder series products in China. Hunan Leo Pump Industry Co., Ltd. is a wholly-owned subsidiary and industrial pump production base established by Leo Co., Ltd. with a total investment of 500 million yuan. Hunan Leo mainly produces large vertical inclined flow pumps, axial flow pumps, split-case double-suction centrifugal pumps, multistage centrifugal pumps, slurry pumps, desulfurization pumps, corrosion-resistant chemical pumps and aluminum process flow pumps. The product line covers more than twenty product series and over 1,000 varieties and specifications, and is widely used in the medium transportation of industries such as water conservancy, irrigation and drainage, petrochemicals, fertilizers, mining, metallurgy, power stations, papermaking, and environmental protection. In accordance with the requirements of the ISO9001:2008 quality management system, the company is equipped with advanced testing and experimental equipment and has established a complete product quality management system.

2.Pump Testing Center

Hunan Liou Pump Industry Co., LTD. Water Pump Testing Center, adhering to the construction principles of high starting point, high technology and high level, aims to build the most advanced water pump testing center in Asia and the leading one in China. The test center covers an area of 4,169 square meters, with a water tank capacity of 13,900 cubic meters (the largest in Asia and the first in the country), a maximum lifting capacity of 80 tons, and a rail height of 17.5 meters. The test center is equipped with a wet pit test bench 13.5 meters deep, a high cavitation dry pit test bench 7 meters deep, 26 meters long and 10 meters wide, as well as three low cavitation test benches. The maximum equivalent diameter of the parallel pipeline is 2.8 meters, the maximum test flow rate is 118.000 m ³ /h, and the maximum test pressure is 12MPa.

The power supply system of the test center adopts two sets of operation systems: industrial frequency and variable frequency. The power supply is mainly equipped with 10kV, 6kV, 3kV and 380V power sources. Six workstations are simultaneously conducting water pump tests. The variable frequency power supply control system can conduct 6-72Hz variable frequency tests on motors and water pumps of different voltage levels of 10kV/6kV/3kV/2300V/1140V.

The testing center is equipped with a fully automatic upper computer measurement and control system, with 88 on-site probes arranged, enabling all-round monitoring of the entire testing center. It combines high-precision detection instruments, sensors and computers to automatically measure, control, collect, process and analyze power parameters and fluid parameters. The test results can be automatically displayed, printed, tabulated and characteristic curves (variable speed, variable diameter, variable Angle) can be drawn. System uncertainty analysis The data in the central control room and the reception room can be displayed synchronously.

The testing center can directly conduct real pump performance tests on various types of pumps such as axial flow pumps, inclined flow pumps, vertical volute pumps, double-suction split-case pumps, multistage pumps, slurry pumps, and cantilever pumps, which can truly grasp the factory performance of the pumps and the research and development effects of the pumps.

3.The application effect of FGI high-voltage variable frequency power supply on the water pump test bench

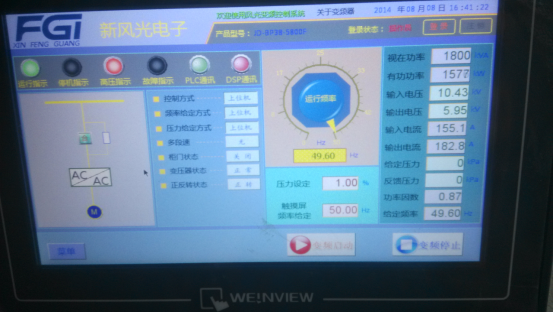

Since its operation, this equipment has shown obvious advantages compared with similar systems in the past. The test interface of the 6kV motor water pump with high-voltage variable frequency power supply. The apparent power of the high-voltage variable frequency power supply is 1800kW, the active power is 1577kW, the input voltage is 10.43kV, the output voltage is 5.95kV, the input current is 155.1A, the output current is 182.8A, and the output frequency is 49.60Hz. The test experiment is very convenient. The high-voltage variable frequency power supply is in operation on site

(1) All parts of the JD-BP38-5800 high-voltage variable frequency power supply produced by Shandong FGI Electronic Technology Development Co., Ltd. are installed in the distribution cabinet and do not require additional equipment such as reactors and filters. It is small in size, compact in structure, easy to install, requires less on-site wiring, has a short commissioning period and can be put into production quickly.

(2) The operating parameters and various indications of the high-voltage variable frequency power supply are all displayed on the touch screen.

(3) The power supply is equipped with a standard communication interface, and the upper computer can fully centrally control the variable frequency power supply through communication.

(4) The variable frequency power supply is very convenient to meet the testing requirements of various motors and water pumps. Just set the corresponding parameters. It can freely drive water pumps of voltage levels such as 10KV/6KV/3kV/2300V/1140V, with a current not exceeding 400A and a frequency ranging from 6 to 72Hz to complete various tests.

(5) It has the same testing effect as imported equipment, greatly reducing the cost of water pump testing.

FGI High-voltage variable frequency power supply human-machine interface

Photos of the equipment in operation on site

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project