-

-

Core manufacturer数字Our AdvantageApplicationOur honor certificate

-

Case classification

1. Introduction

Belt conveyors are widely used in ports, especially in some large ports. When the belt conveyor is at rest or in operation, a large amount of energy is stored inside the belt. During the start-up process, if a soft start device is not installed, excessive tension waves can easily cause the belt to be torn. Therefore, in the safety regulations of some industries, belt conveyors must be equipped with soft start devices. With the continuous progress and improvement of high-voltage variable frequency technology, in newly-built ports, variable frequency speed control is given priority for belt conveyor equipment.

2.Project introduction

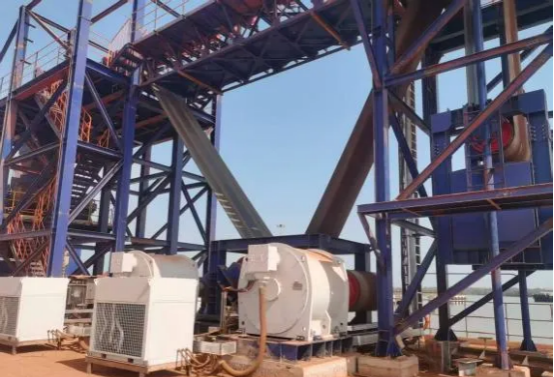

Guinea is the world's largest producer of bauxite and mainly exports bauxite to its freight ports. The main belt conveyor is used to transport bauxite from the material yard to the cargo ship loading platform. The belt conveyor is driven by two motors working simultaneously.

After conducting research on various medium voltage drive manufacturers and comparing solutions, the freight port of Guinea ultimately chose the FGIG74 series of new-generation high-voltage frequency converters as the control equipment for belt conveyors, which is used to achieve soft start, soft stop, speed regulation, power balance and other controls of belt conveyors.

3.Variable frequency control scheme for belt conveyor

The FGI high and low voltage series frequency converters are suitable for belt conveyor applications in various industries and can provide comprehensive power solutions for different loads, meeting a wide range of demands.

Motor parameter self-learning, accurately learning the motor parameters and achieving effective control.

Fiber optic control, the host and slave units can be interchanged at any time;

The control methods for the host and slave units are flexible.

Supports master-slave control for multiple motors;

Support the thermal standby technology of the frequency converter.

4. Master-slave control

This scheme uses two frequency converters to drive two motors respectively, and the stator windings of each motor are directly connected to the output of the corresponding frequency converters respectively. The two-motor frequency conversion system is composed of two completely independent frequency converters, which communicate synchronously through the master and slave machines. Ensure the rotational speed and power balance of the two motors. Either of the two motors can be used as the main unit, and the other one is the slave unit. In the two-machine drive scheme, the frequency converter independently controls the motor, and the master and slave of the frequency converter can automatically adjust the output power of the frequency converter to be consistent.

5. Variable frequency electrical control system for belt conveyor

When starting the vehicle, only after judging that the signals transmitted by each system are normal can the next procedure be entered.

When all parts of the belt conveyor meet the starting conditions, a start signal is issued. The frequency converter outputs the corresponding frequency and voltage according to the given operation signal.

At the same time, the operation console issues an instruction to open the brake. If the brake is not opened or not fully opened, an emergency stop signal will be given to the frequency converter simultaneously.

When the belt reaches the rated speed, the speed of the belt and the speed of the drum are detected. When the difference between the two speeds exceeds the specified value, an emergency stop will occur.

6. Application performance

The belt conveyor has truly achieved soft startup.

By slowly starting the motor to drive the belt conveyor, the impact during start-up and shutdown can be minimized.

Reduce the tape strength

As the starting time of the frequency converter can be adjusted within the range of 1 to 3600 seconds, it reduces the starting impact and mechanical loss.

Power balance

By adopting an excellent master-slave control method, the motor torque and power balance are achieved.

Testing function

The variable frequency speed control system enables stepless speed regulation and can operate at any speed in the no-load state.

Smooth heavy-load startup

The frequency converter can output 2.2 times the rated torque when running at low speed, which is suitable for heavy-load startup.

Energy conservation

The belt speed can be adjusted according to the load conditions, which can save electricity and reduce the wear of the belt.

6.TAG

The drive system of the belt conveyor adopts the FGI G74 series medium voltage drive, which can adjust the output frequency according to the load conditions, avoiding the waste of motor power and improving energy utilization efficiency. As the global emphasis on energy conservation and environmental protection continues to increase, the application of high-voltage frequency converters in belt conveyors will become more widespread, helping enterprises reduce energy consumption costs and achieve green production.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project