-

-

Core manufacturer数字Our AdvantageApplicationOur honor certificate

-

Case classification

1. Industry Overview

Steel plate shearing machines, also known as shearing machines or slitting machines, are machines that unwind, strand, braid, and shear steel plates of varying lengths and widths from coiled steel plates of varying specifications. These machines can process a variety of cold-rolled and hot-rolled coils, silicon steel plates, stainless steel plates, color-coated plates, aluminum plates, and various types of electroplated or painted metal plates. They are widely used in metal plate processing industries such as automotive manufacturing, containers, home appliances, food, packaging, and building materials.

Steel plate shearing machines can be broadly categorized as cross-cutting and longitudinal-cutting. Due to the process, longitudinal-cutting requires simple control and can be driven by a standard inverter. Cross-cutting, due to its high precision requirements, often utilizes a servo system for control, but the high-power servo system is more expensive.

Energy inverters have been successfully deployed in plate shearing machines, providing precise and reliable operation in the cross-cutting control area, earning widespread customer acclaim. Below, we introduce an application case where the FD100 engineering-type vector inverter replaced a high-power servo drive from a Japanese manufacturer.

2.Equipment Introduction

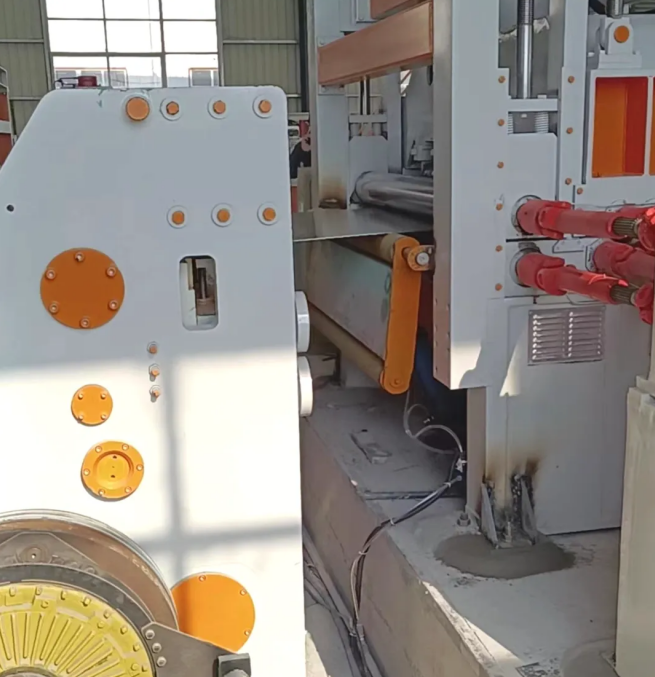

The shearing machine utilizes a PLC-based centralized control system with a human-machine interface (HMI) display. Parameters such as quantity, length, width, and cutting speed can be customized to meet user requirements. The entire system consists of a loading cart, unwinder, winder, scrap winder, feeder, large shears, and a finished plate conveyor line. A swing-type intermediate bridge, a clamping and feeding device, and a guide system are installed between each machine, making this an automatic coil handling system that integrates mechanical, electrical, hydraulic, and pneumatic functions.

3. System configuration

The on-site equipment control scheme has been changed from the original high-power servo system to a control scheme of FD100 engineering vector frequency converter + multi-functional PG card + asynchronous motor. The multi-functional PG card can simultaneously receive pulse instructions issued by the PLC, speed feedback pulse signals from the motor encoder, and feedback pulse signals from the product length detection encoder, achieving dual closed-loop control.

4.Product superiority

Reduced costs, simple operation, and energy savings

This equipment uses the Energ FD100 frequency converter system, replacing an imported servo system. This achieves the same servo-like performance while reducing system design and maintenance costs. Operation is simple, convenient, and energy-efficient.

Fast response speed and high speed stability accuracy

The FD100 engineering-grade vector frequency converter is feature-rich and offers superior performance. The expansion PG card enables dual closed-loop control, resulting in fast system response and speed stability accuracy within 0.1%. This ensures extremely precise feed lengths and perfectly meets cut sheet length tolerances, resulting in excellent performance.

Smooth and rapid start and stop ensures rapid system response and synchronized, stable operation.

The FD100 frequency converter drives the motor with closed-loop control, achieving a starting torque of 180% of rated torque. This enables smooth and rapid start and stop, rapid system response, and synchronized, stable operation.

Comprehensive protection features ensure safe and reliable operation.

Comprehensive protection features for overcurrent, overvoltage, undervoltage, and overload ensure safe and reliable operation.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project