Recently, the "3300V mine flameproof and inherently safe voltage terminal compensator" product developed by FGI Science And Technology Co., Ltd. was successfully put into use in the fully mechanized mining face of Huaihe Energy West Coal electric Serian 2 mine, effectively solving the problem of on-site long-distance line voltage drop, and realizing the long distance normal start-up operation of shearer power supply.

Using a number of core technologies mastered by itself, combined with the actual scene needs of the mine, FGI first 3300V long-distance power supply device, obtained the first set of coal safety + explosion-proof certificate in China in June 2024, has been concerned and recognized by major energy groups, and took the lead in Huaihe Energy put into use. It marks that the first set of 3300V long-distance power supply device in China has passed the market verification, and FGI helps to promote the construction process of smart mines with practical actions.

1.Defect

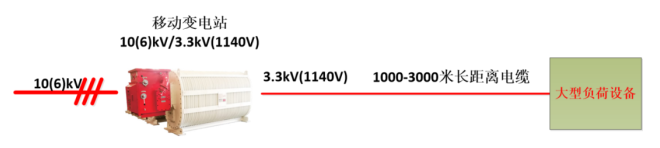

The power supply distance between the related equipment and the supporting power supply is generally more than 1000 meters. At such a long power supply distance, the cable voltage drop caused by the reactive power and active power current during the operation of the motor causes the low voltage at the end of the power supply cable.

Because the shearer, boring machine such as the direct start of the load has a maximum of 7-10 times the current impact, according to the lower the voltage the greater the current, so the longer the power supply distance the greater the line loss, the lower the voltage at the end of the actual line the lower the load equipment can not start normally. In order to achieve "long-distance power supply" coal mining enterprises generally take the following measures:

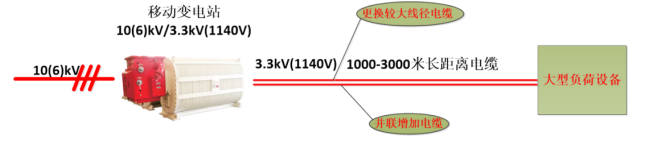

Measure 1: Connect multiple cables in parallel or replace cables with larger diameters

The equivalent impedance of the cable is reduced under the same transmission length, thus reducing the voltage drop on the cable, but increasing the input of the cable cost.

Measure 2: Increase the voltage of the first power supply

To make up for the loss on the line, but this will cause the equipment to stop or no-load operation when the end voltage is high, causing a certain threat to the insulation voltage of the cable and equipment.

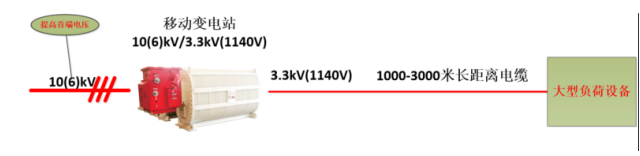

Measure three: Move the position of the mobile transformer forward

Reduce the length of the power supply cable between the related equipment and the power supply, thereby reducing the voltage drop on the cable, and frequently moving the power transformation equipment will bring greater inconvenience and construction costs.

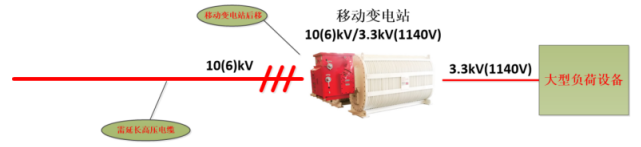

2.FGI Solutions

In view of the trouble of long-distance power supply in fully mechanized mining face, FGI company proposed an innovative scheme. Based on compensating reactive current, it dynamically and real-time regulates the power supply voltage of the power supply terminal equipment and compensates the voltage drop caused by the active current on the cable, so as to ensure the voltage requirement of the working power supply of the end equipment.

Program advantages:

There are many control modes for reactive power compensation of long distance power supply integrated treatment device, including constant device reactive power mode and constant test point reactive power mode. It can improve the power factor of the working face to 0.99 from the system level, filter out the harmonics of the grid, improve the transmission and power supply capacity of the power supply line, and save energy and reduce consumption.

Developed with phase compensation load voltage feedback control and load line voltage drop feedforward control combined with the composite control strategy design, under the premise of ensuring the stable accuracy of the power supply end voltage, can greatly improve the response speed of voltage compensation, dynamic response time is not more than 20 ms.

Research line impedance voltage drop adaptive algorithm, according to line diameter specifications, line length, load current adaptive calculation of line impedance voltage drop, can improve the adaptability of the device to a variety of different application sites, can ensure that the downhole equipment when starting voltage compensation to 97% of the rated grid voltage. The grid voltage value can be compensated to 99% of the rated grid voltage during full load operation.

3.application performance

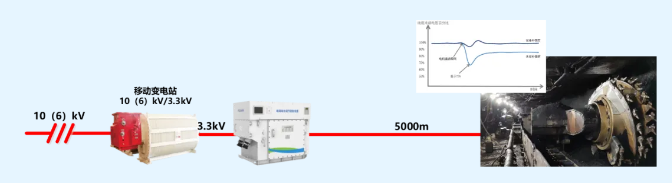

The product has successfully broken through the industry bottleneck of long distance power supply of fully mechanized mining face in coal mine, and can achieve 5000 meters power supply distance of coal face under 3300V voltage, which not only helps to improve the coal production efficiency, but also reduces the production cost and improves the reliability of power supply. In addition, by improving the power supply process of the mining face, the number of people employed in the coal mine face can be greatly reduced, the labor intensity of miners can be reduced, and the work safety can be improved, which is an indispensable part of the construction of underground smart mines.

4. Customer value

"Flameproof and intrinsically safe voltage terminal compensator for mine" can reduce the mine construction cost of coal mine enterprises by reducing the cable diameter. In addition, the equipment can flexibly choose the location, without moving transformers, reduce the development of contact lanes, and achieve long-distance power supply for ultra-long working faces at a time of operation, effectively improve the efficiency of coal mining, and bring considerable economic benefits to coal mining enterprises.