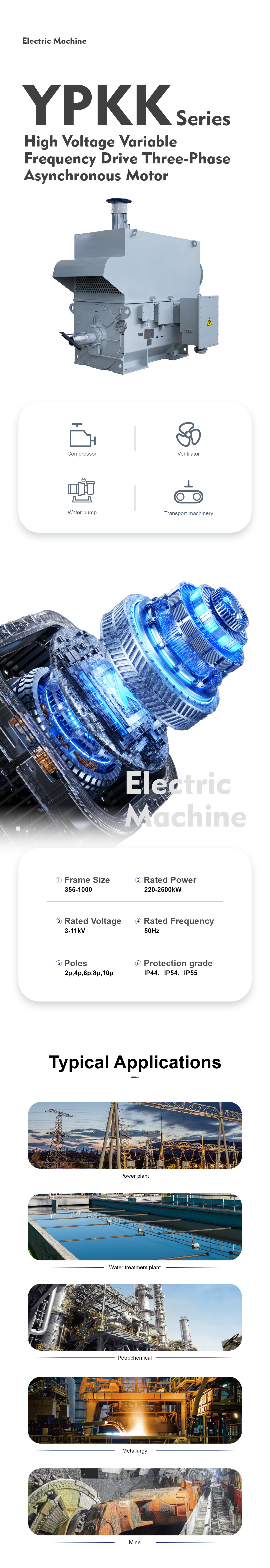

YPKK series high voltage variable frequency drive three-phase asynchronous motor

The YPKK series high-voltage variable frequency drive three-phase asynchronous motor is a high-performance motor specially designed for industrial variable frequency speed regulation scenarios. It integrates box structure, wide speed regulation range and high reliability, and is widely used in heavy industry.

●Frame Size: 355-1000

●Rated Power: 220-2500kW

●Rated Volyage:3-11kV

●Rated Frequency: 50Hz

●Poles: 2p,4p,6p,8p,10p

●Protaction Grade: IP44, IP54, IP55